Countershaft Reassembly

Countershaft Reassembly

Special Tools Required

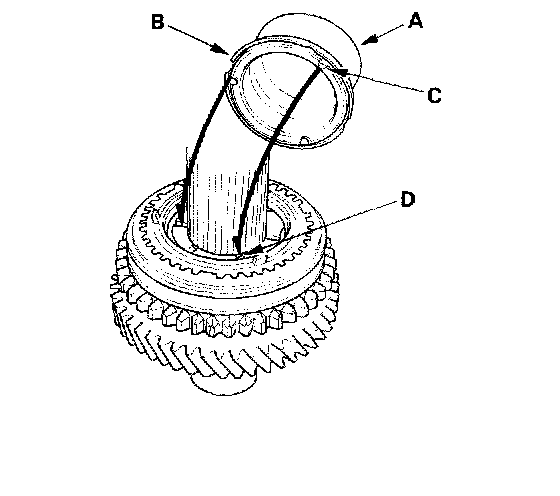

- Driver, 40 mm I.D. 07746-0030100

- Attachment, 30 mm 07746-0030300

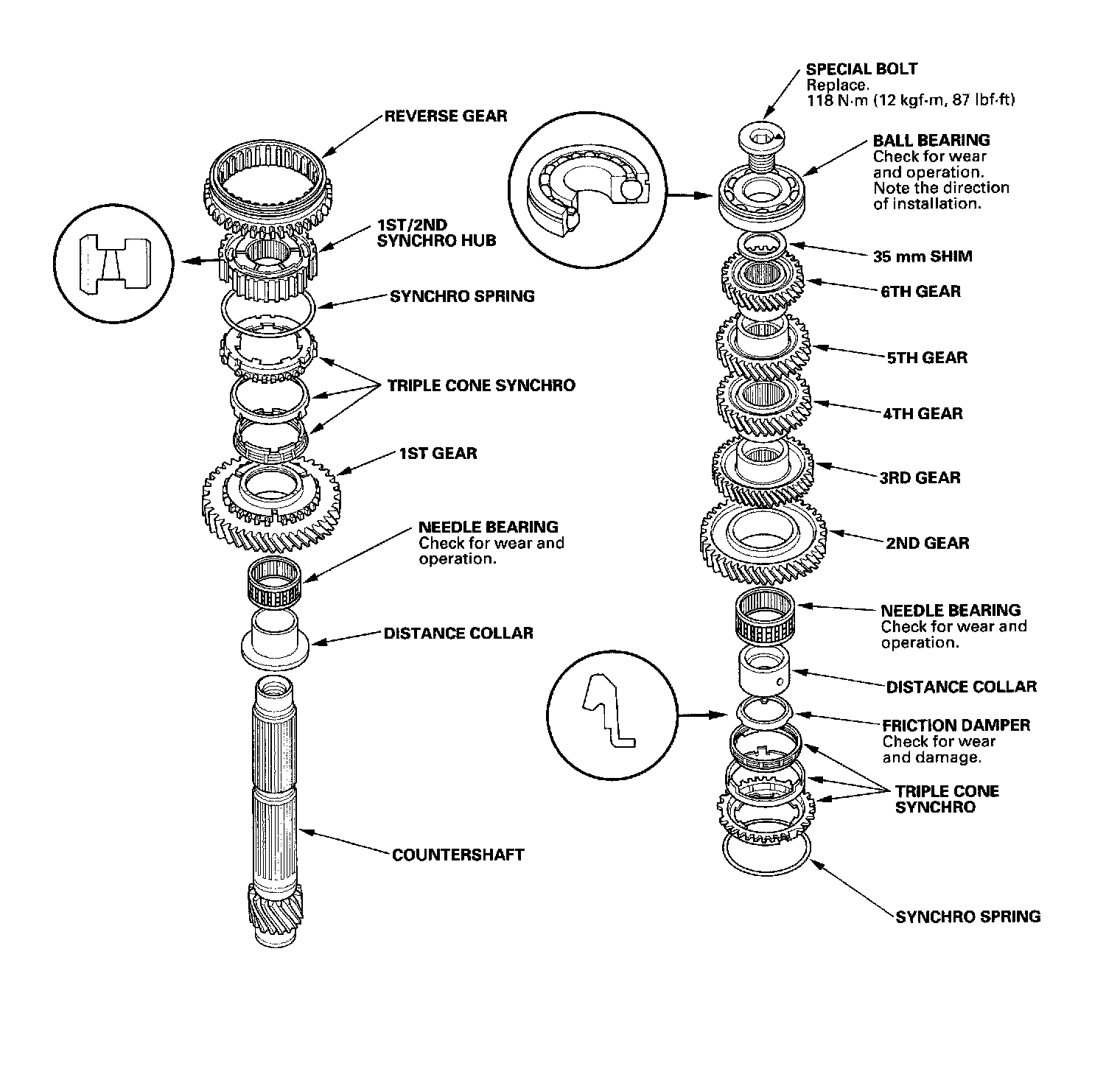

NOTE: Refer to the Exploded View as needed during this procedure.

1. Clean all parts in solvent, dry them, and apply lubricant to all contact surfaces.

2. Install the distance collar and needle bearing onto the countershaft.

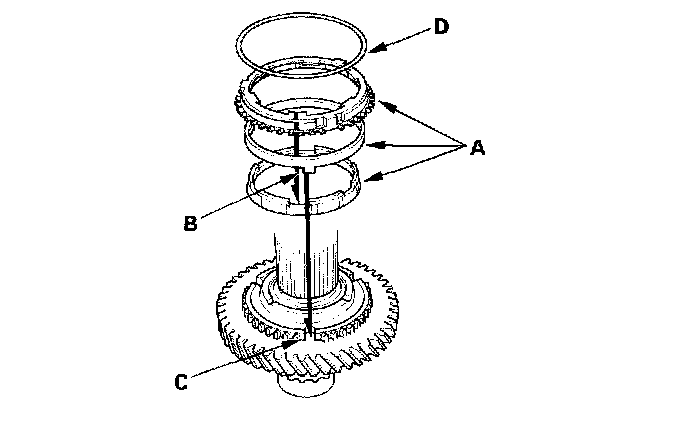

3. Install the triple cone synchro assembly (A) by aligning the synchro cone fingers (B) with 1st gear grooves (C), then install the synchro spring (D).

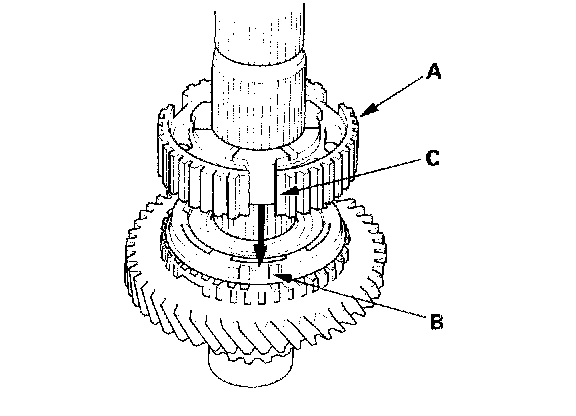

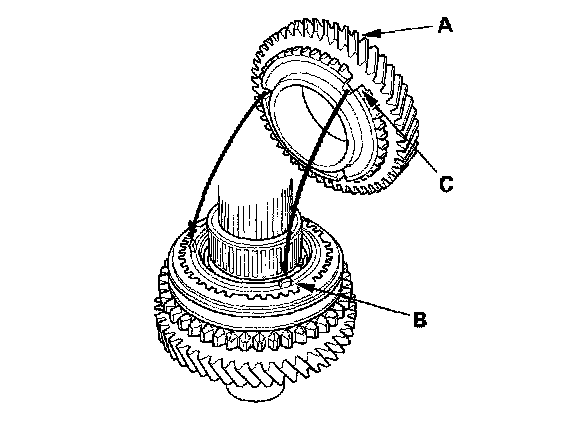

4. Install the 1st/2nd synchro hub (A) by aligning the synchro cone fingers (B) with the 1st/2nd synchro hub grooves (C).

5. Install the reverse gear.

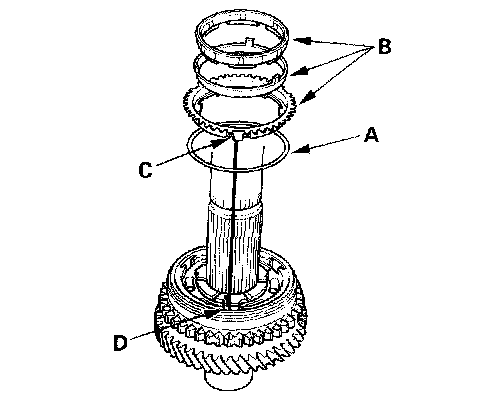

6. Install the synchro spring (A).

7. Install the triple cone synchro assembly (B) by aligning the synchro cone fingers (C) with the 1st/2nd synchro hub grooves (D).

8. Install the distance collar (A) and friction damper (B) by aligning the friction damper fingers (C) with the 1st/2nd synchro hub grooves (D).

9. Install the needle bearing.

10. Install the 2nd gear (A) by aligning the synchro cone fingers (B) with the 2nd gear grooves (C).

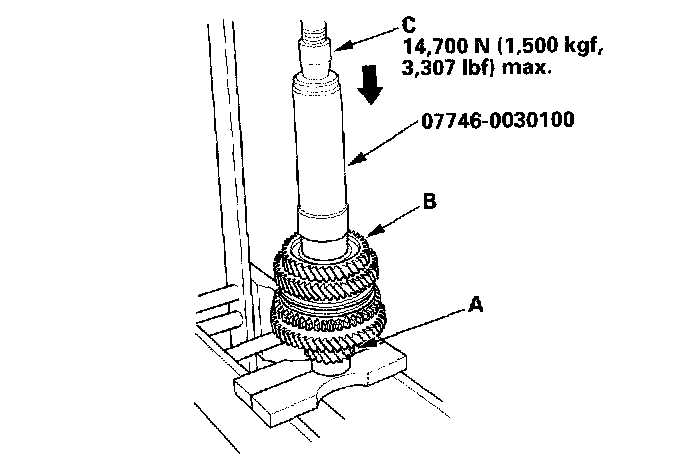

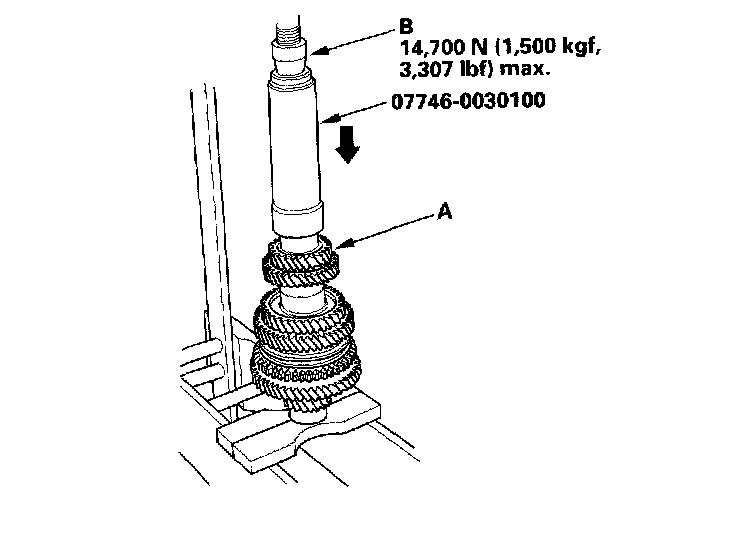

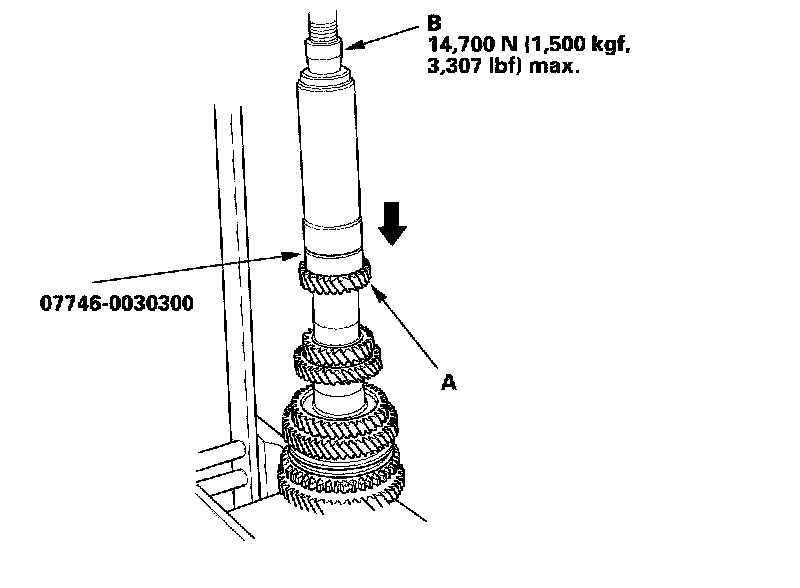

11. Support the countershaft (A) on the steel blocks, then install 3rd gear (B) using the special tool and a press (C). Do not exceed the maximum pressure.

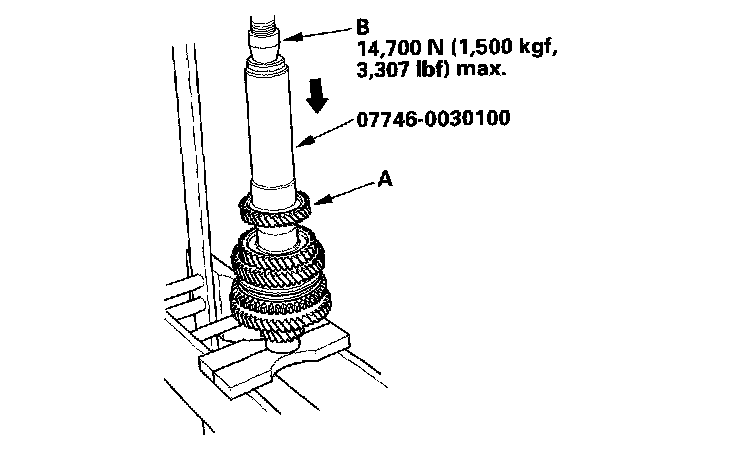

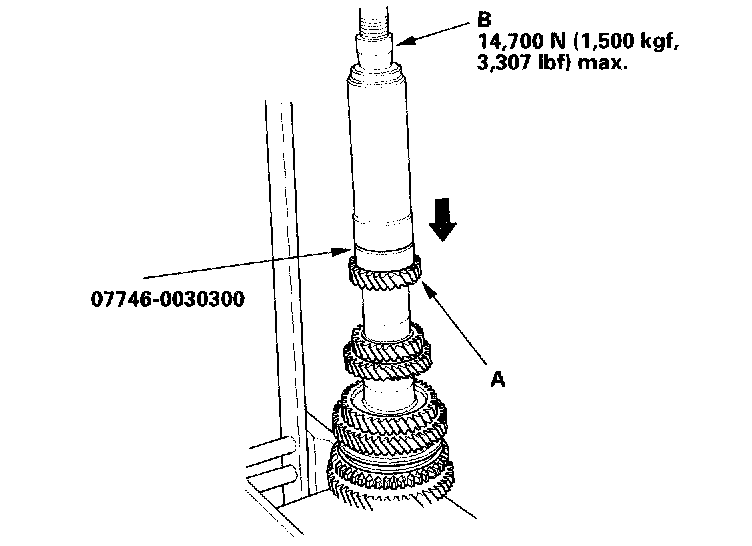

12. Install the 4th gear (A) using the special tool and a press (B). Do not exceed the maximum pressure.

13. Install the 5th gear (A) using the special tool and a press (B). Do not exceed the maximum pressure.

14. Install 6th gear (A) using a special tools and a press (B). Do not exceed the maximum pressure.

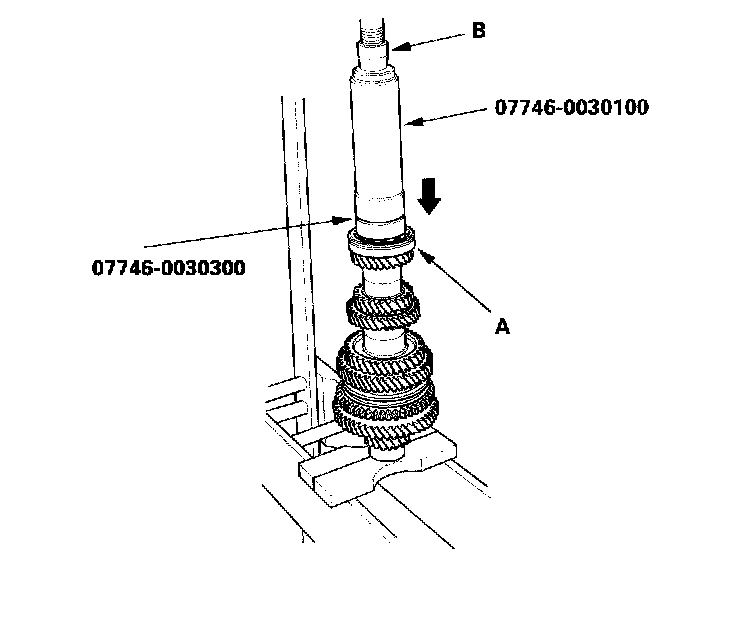

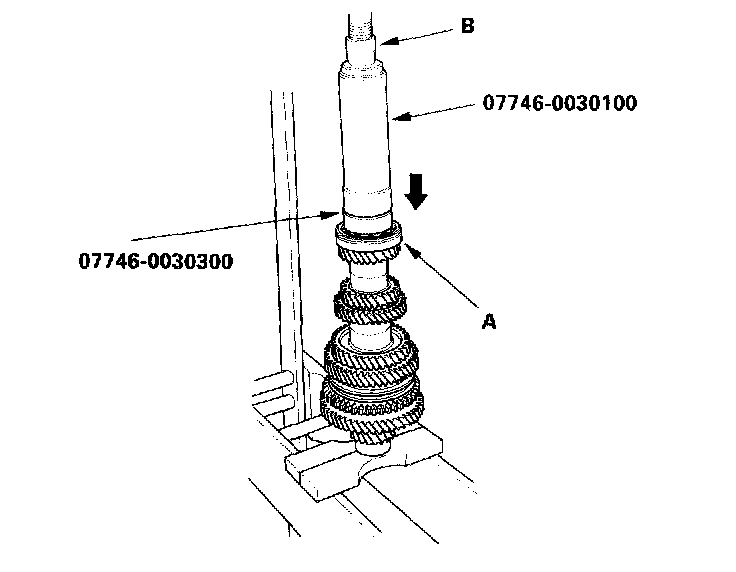

15. Install the 35 mm shim and the old ball bearing (A) using a special tools and a press (B).

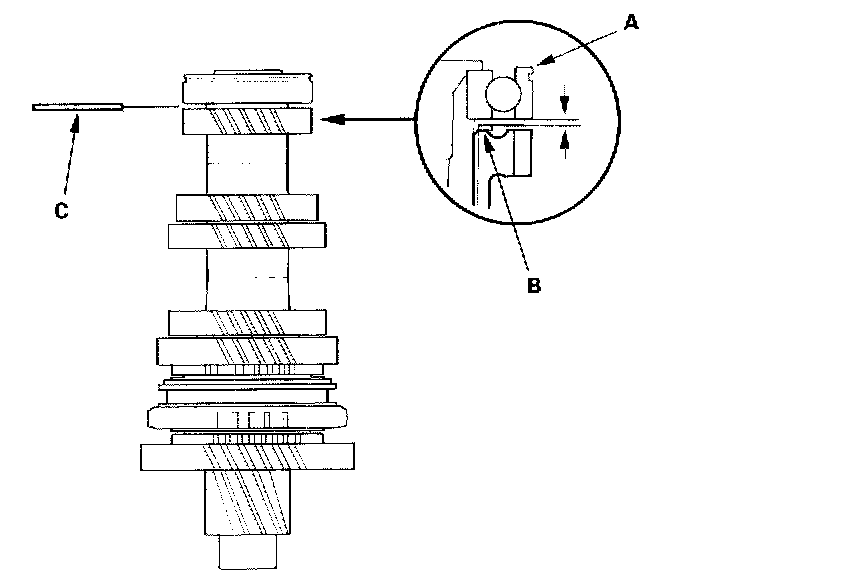

16. Measure the clearance between the old bearing (A) and the 35 mm shim (B) with a feeler gauge (C).

Standard: 0.04 - 0.10 mm (0.0016 - 0.0039 inch)

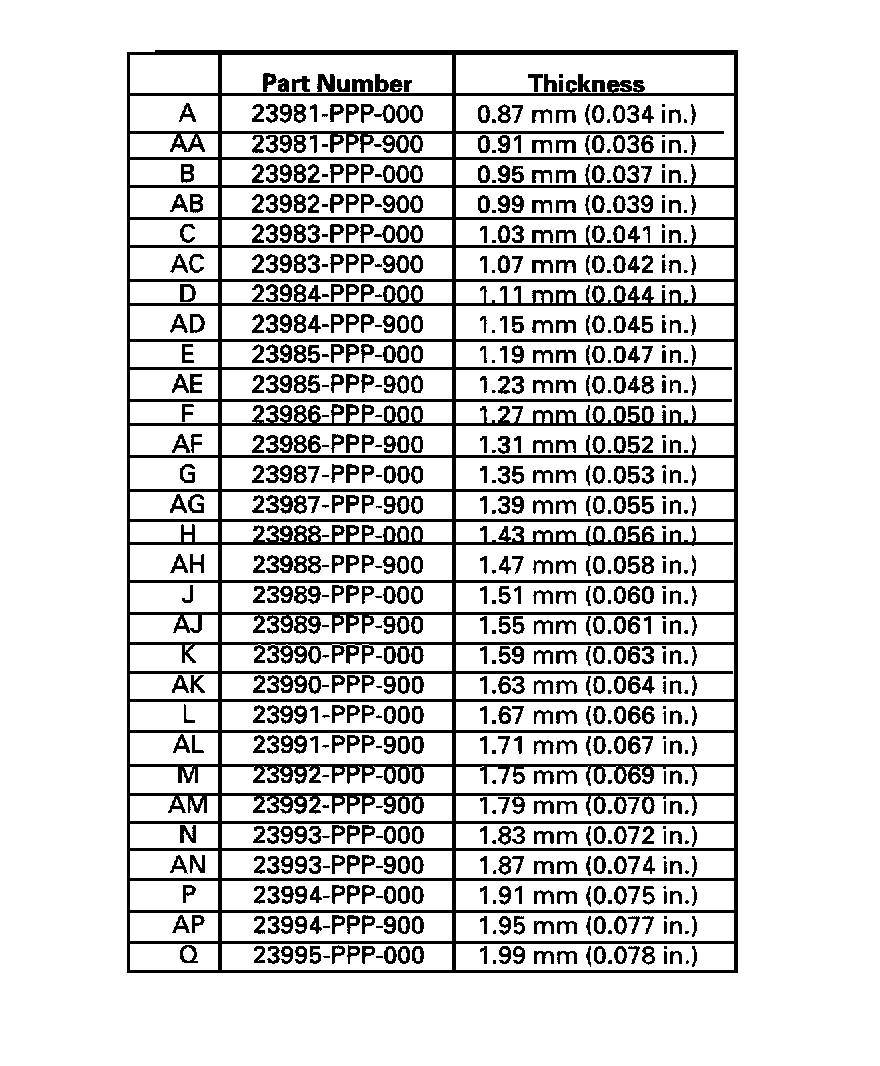

17. If the clearance is more than the standard, select a new shim from the table shown. If the clearance measured in step 16 is within the standard, replace only the ball bearing.

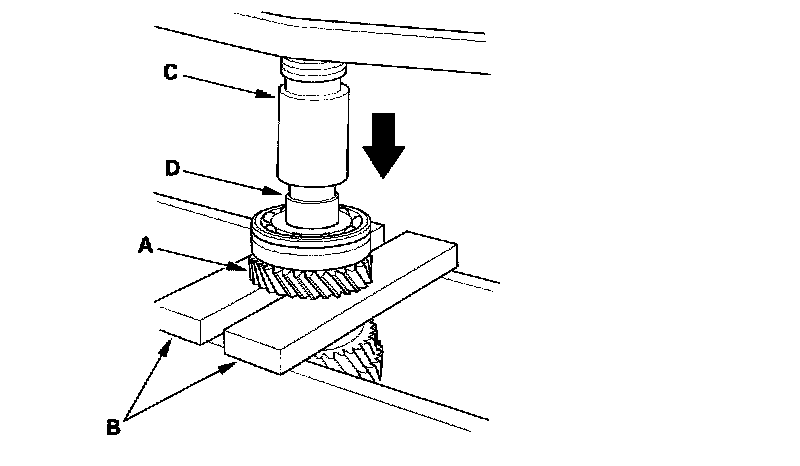

18. Support the 6th gear (A) on steel blocks (B), then use a press (C) and an attachment (D) to press the countershaft out of the ball bearing.

19. If necessary, install the 35 mm shim selected in step 17, then recheck the clearance.

20. Install 6th gear (A) using a special tools and a press (B). Do not exceed the maximum pressure.

21. Install the new ball bearing (A) using a special tools and a press (B).

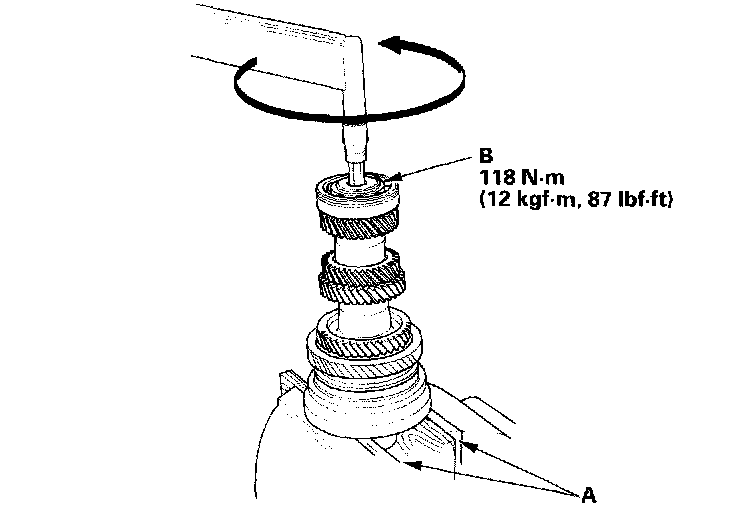

22. Securely clamp the countershaft assembly in a bench vise with wood blocks (A).

23. Tighten the new special bolt (B) (left-hand threads).