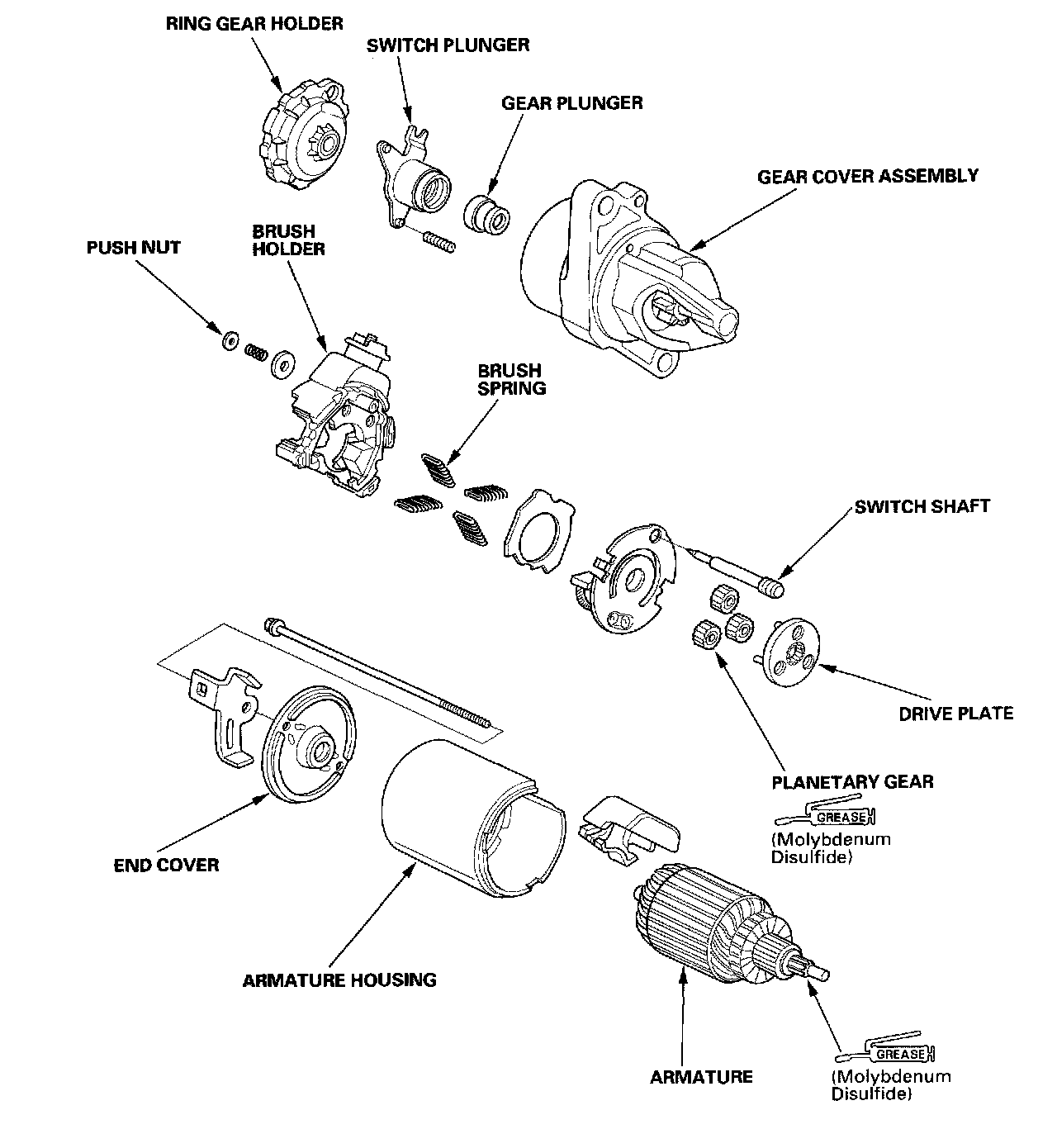

Disassembly and Reassembly

Starter Overhaul - Disassembly/Reassembly:

Starter Overhaul

Armature Inspection and Test

1. Remove the starter.

2. Disassemble the starter as shown at the beginning of this procedure.

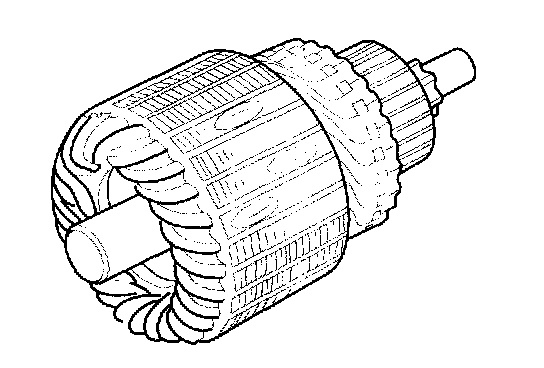

3. Inspect the armature for wear or damage from contact with the permanent magnet. If there is wear or damage, replace the armature.

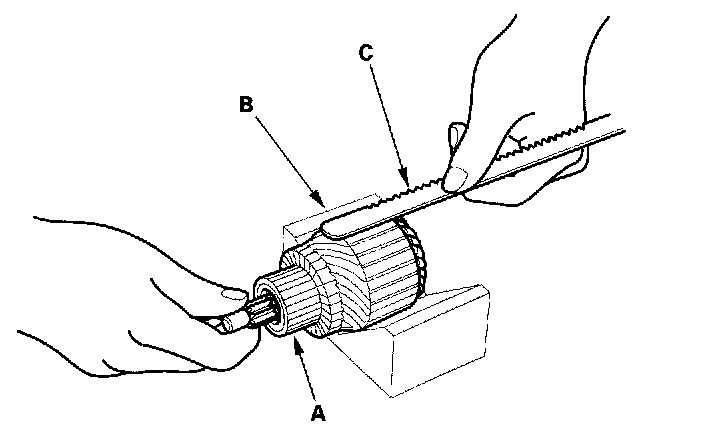

4. Check the commutator (A) surface. If the surface is dirty or burnt, resurface with emery cloth or a lathe within the given specifications, or recondition with #500 or #600 sandpaper (B).

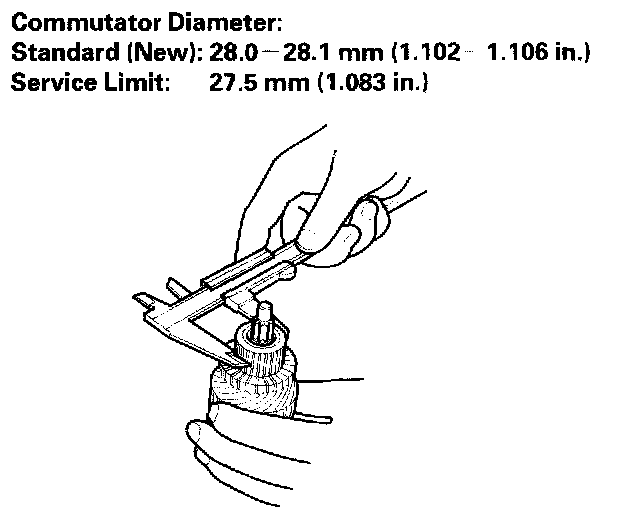

5. Check the commutator diameter. If the diameter is below the service limit, replace the armature

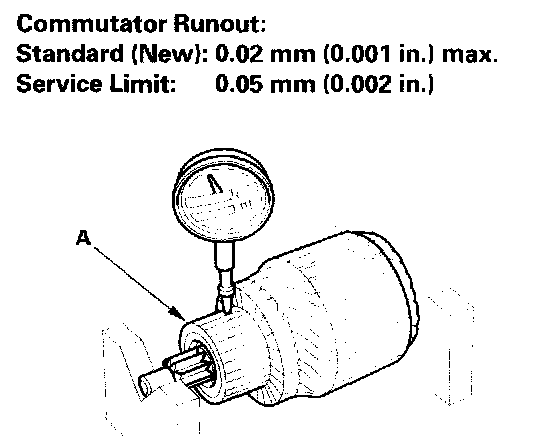

6. Measure the commutator (A) runout.

- If the commutator runout is within the service limit, check the commutator for carbon dust or brass chips between the segments.

- If the commutator runout is not within the service limit, replace the armature.

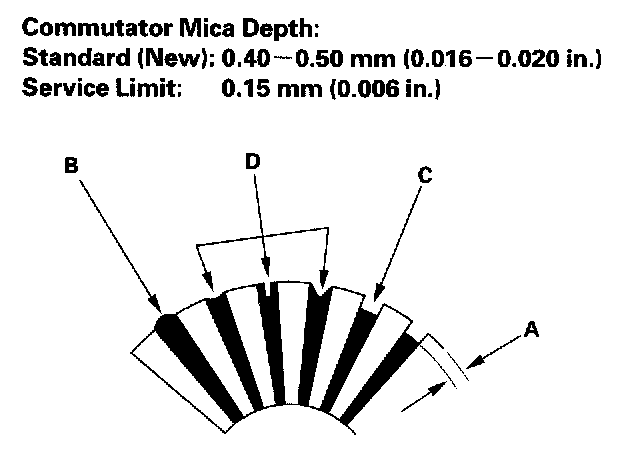

7. Check the mica depth (A). If the mica is too high (B), undercut the mica with a hacksaw blade to the proper depth. Cut away all the mica (C) between the commutator segments. The undercut should not be too shallow, too narrow, or V-shaped (D).

8. Check for continuity between the segments of the commutator. If an open circuit exists between any segments, replace the armature.

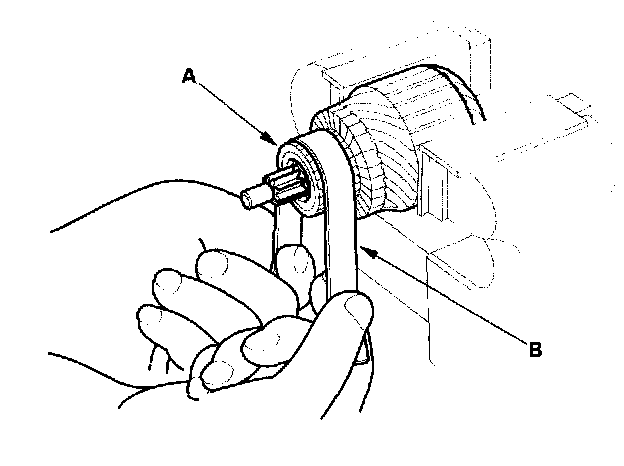

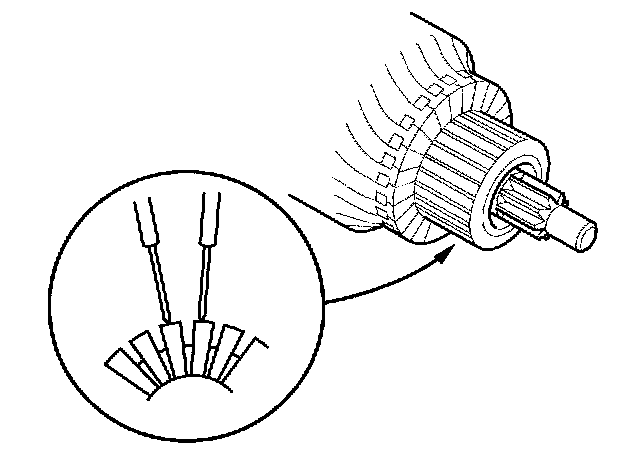

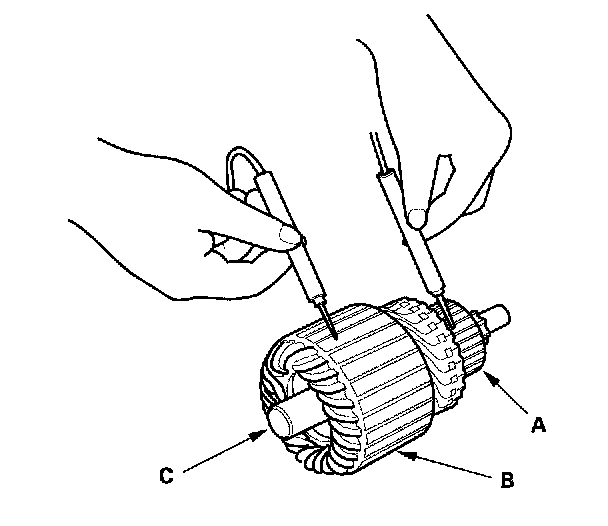

9. Place the armature (A) on an armature tester (B). Hold a hacksaw blade (C) on the armature core. If the blade is attracted to the core or vibrates while the core is turned, the armature is shorted. Replace the armature.

10. Check with an ohmmeter that no continuity exists between the commutator (A) and armature coil core (B), and between the commutator and armature shaft (C). If continuity exists, replace the armature.

Starter Brush Inspection

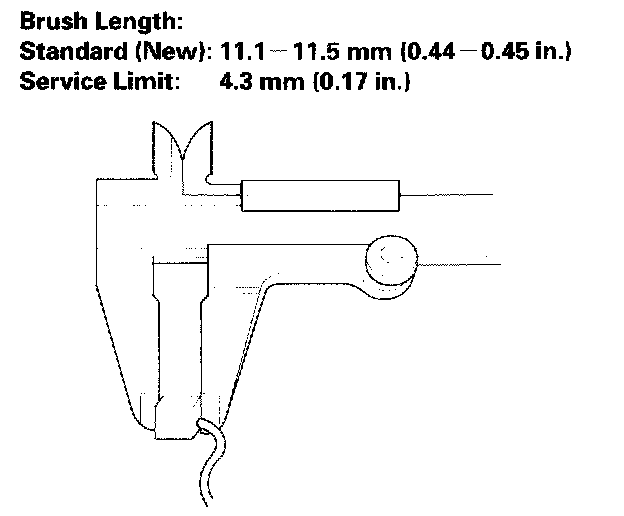

11. Measure the brush length. If it is shorter than the service limit, replace the brush holder assembly.

Starter Brush Holder Test

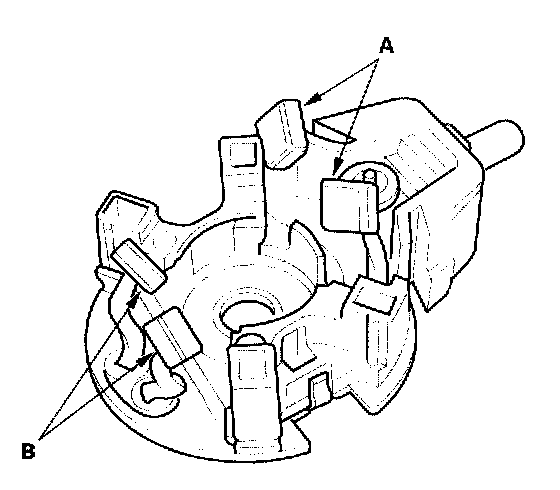

12. Check that there is no continuity between the (+) brush (A) and (-) brush (B). If there is continuity, replace the brush holder assembly.

Planetary Gear Inspection

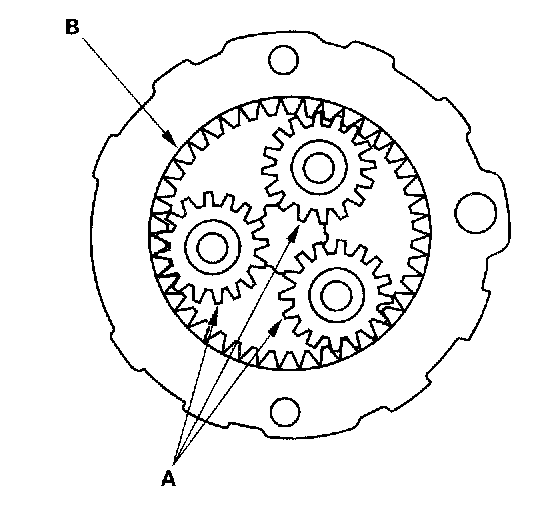

13. Check the planetary gears (A) and ring gear (B). Replace them if they are worn or damaged.

Overrunning Clutch Inspection

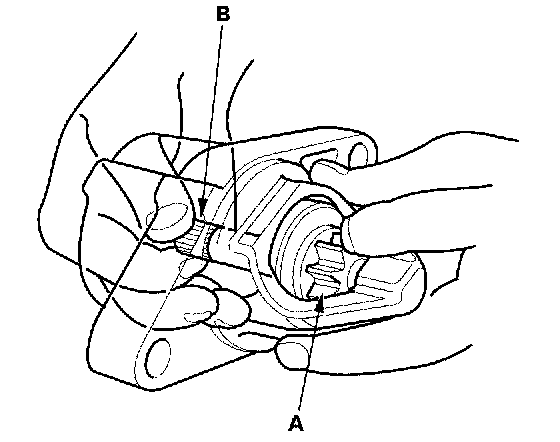

14. While holding the drive gear (A), turn the gear shaft (B) clockwise. Check that the drive gear comes out to the other end If the drive gear does not move smoothly, replace the gear cover assembly.

15. While holding the drive gear, turn the gear shaft counterclockwise. The gear shaft should rotate freely. If the gear shaft does not rotate smoothly, replace the gear cover assembly.

16. If the starter drive gear is worn or damaged, replace the overrunning clutch assembly; the gear is not available separately.

Check the condition of the torque converter ring gear to see if the teeth are damaged

Starter Reassembly

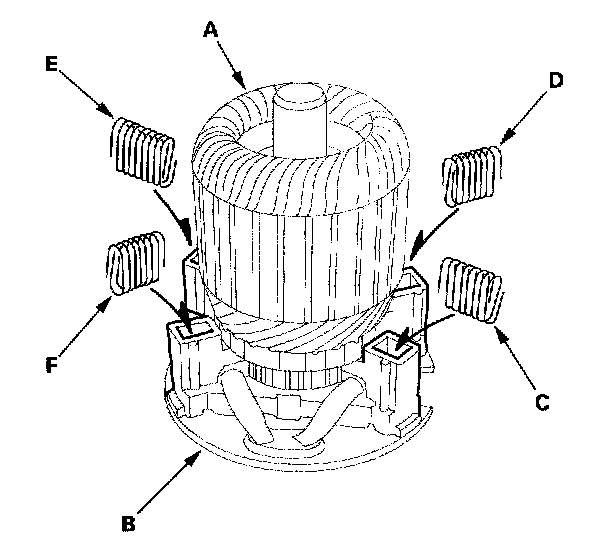

17. Install the brush into the brush holder, and set the armature (A) in the brush holder (B).

NOTE: To seat the new brushes, slip a strip of #500 or #600 sandpaper, with the grit side up, between the commutator and each brush, and smoothly rotate the armature. The contact surface of the brushes will be sanded to the same contour as the commutator.

18. While squeezing a spring (C), insert it in the hole on the brush holder, and push it until it bottoms. Repeat this for the other three springs (D, E and F).

19. Install the armature and brush holder assembly into the housing.

NOTE: Make sure the armature stays in the holder.