P0497

DTC P0497: EVAP System Low Purge FlowSpecial Tools Required

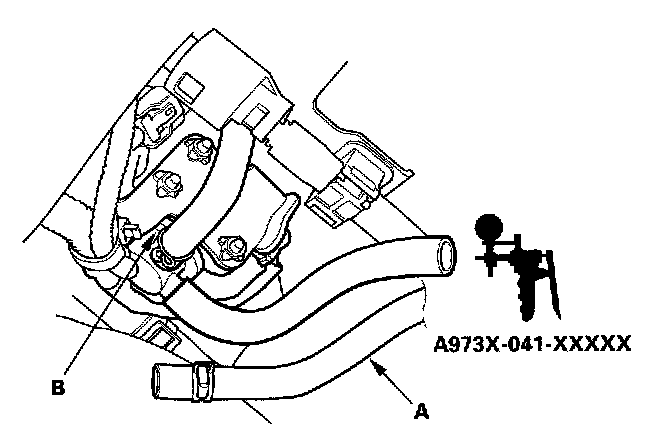

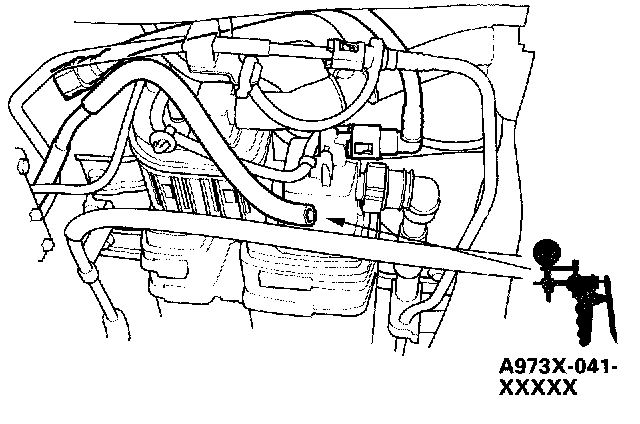

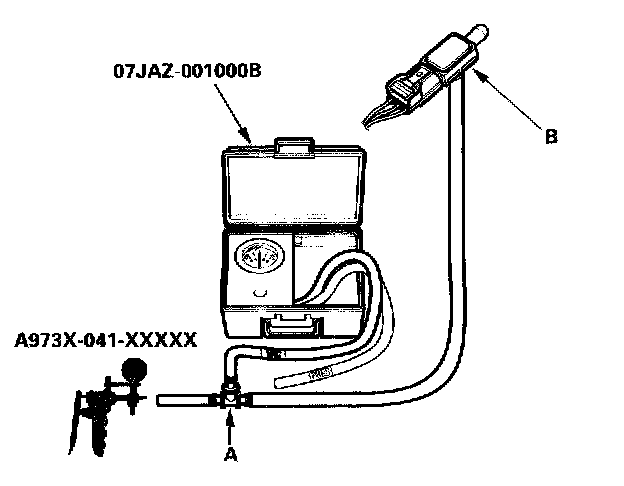

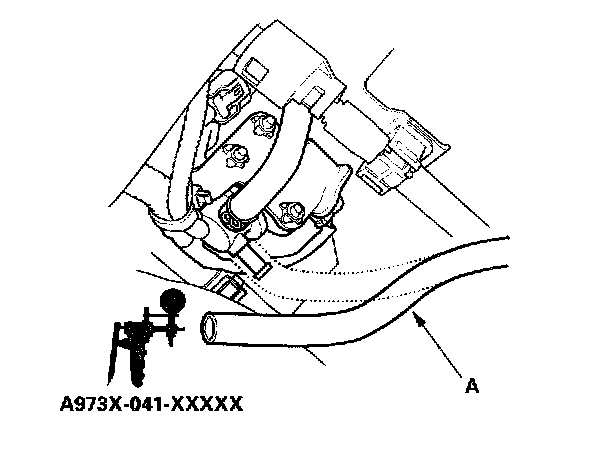

- Vacuum pump/Gauge, 0 - 30 in.Hg A973X-041-XXXXX

- Vacuum/Pressure Gauge, 0 - 4 in.Hg 07JAZ-001000B

1. Check the fuel fill cap (the cap must say "If not tightened 3 clicks check engine light may come on").

Is the correct fuel fill cap installed and properly tightened?

YES - Go to step 2.

NO - Replace or tighten the cap, then go to step 22.

2. Turn the ignition switch ON (II).

3. Clear the DTC with the HDS.

4. Do the EVAP FUNCTION TEST in the INSPECTION MENU with the HDS.

Is the result OK?

YES - Intermittent failure, system is OK at this time. Check for poor connections or loose terminals at the FTP sensor, the EVAP canister purge valve, or the EVAP canister vent shut valve and the ECM/PCM.

NO - Go to step 5.

5. Check for a loose or damaged PCS/CPV line between the intake manifold and the EVAP canister purge valve.

Is the line OK?

YES - Go to step 6.

NO - Reconnect or repair the PCS/CPV line, then go to step 22.

6. Disconnect the vacuum hose (A) from the EVAP canister purge valve (B) in the engine compartment, and connect a vacuum pump to the EVAP canister purge valve.

7. Do the EVAP PCS/CPV ON in the INSPECTION MENU with the HDS.

8. Slowly apply about 0.6 in.Hg (15 mmHg) of vacuum the hose.

Does it hold vacuum?

YES - Check for blockage on the PCS/CPV line between the intake manifold and the EVAP canister purge valve. If the vacuum hose is OK, replace the EVAP canister purge valve, then go to step 22.

NO - Go to step 9.

9. Reconnect the vacuum hose to the EVAP canister purge valve.

10. Disconnect the vacuum hose from the PCS/CPV line (EVAP canister side), and connect a vacuum pump to the hose.

11. Do the EVAP PCS/CPV ON in the INSPECTION MENU with the HDS.

12. Slowly apply about 0.6 in.Hg (15 mmHg) of vacuum to the hose.

Does if hold vacuum?

YES - Check for a restricted PCS/CPV line between the EVAP canister purge valve and the EVAP canister, then go to step 22.

NO - Go to step 13.

13. Remove the FTP sensor with its connector connected.

14. Connect a T-fitting (A) from the vacuum gauge and the vacuum pump to the FTP sensor (B) as shown.

15. Slowly apply about 0.4 in.Hg (10 mmHg) of vacuum to the hose.

16. Check the FTP SENSOR in the DATA LIST with the HDS.

Is the difference more than 1.1 kPa (8 mmHg, 0.31 in.Hg) before and after applying vacuum?

YES - Go to step 17.

NO - Replace the FTP sensor, then go to step 22.

17. Reconnect the vacuum hose to the PCS/CPV line (EVAP canister side) and reinstall the FTP sensor

18. Disconnect the vacuum hose (A) from the PCS/CPV line (EVAP canister purge valve side), and connect a vacuum pump to the hose.

19. Do the EVAP CVS ON in the INSPECTION MENU with the HDS.

20. Slowly apply about 0.6 in.Hg (15 mmHg) of vacuum to the hose.

Does the hose hold vacuum?

YES - Check for blockage at the EVAP canister port, then go to step 21.

NO - Replace the EVAP canister vent shut valve, then go to step 21.

21. Install the FTP sensor.

22. Reconnect all hoses.

23. Turn the ignition switch ON (II).

24. Reset the ECM/PCM with the HDS.

25. Do the ECM/PCM idle learn procedure.

26. Do the EVAP FUNCTION TEST in the INSPECTION MENU with the HDS.

Is the result OK?

YES - Troubleshooting is complete.

NO - Check for poor connections or loose terminals at the FTP sensor, the EVAP canister purge valve, or the EVAP canister vent shut valve and the ECM/PCM, then go to step 1.